What Are Sliding Table Panel Saw NikMann S-350-cnc?

Sliding table panel saws NikMann S-350-cnc, are essential for any woodworking shop in Australia, offering precision, versatility, and safety. They are a valuable investment for both new purchases and ongoing maintenance. This guide covers everything you need to know to make informed decisions.

One of the key reasons woodworkers choose sliding table panel saws is their exceptional accuracy. The sliding table keeps the workpiece stable throughout the cut, minimizing errors—especially useful for repeated cuts and large projects.

These machines can handle a variety of materials, including PVC, ABS, veneer, and more. When selecting a panel saw, ensure it is compatible with the materials you work with.

How to Maintain Your Sliding Table Panel Saw

Proper maintenance is crucial to keep your sliding table panel saw in top condition. Here are some tips to ensure your saw remains reliable and efficient.

REGULAR CLEANING

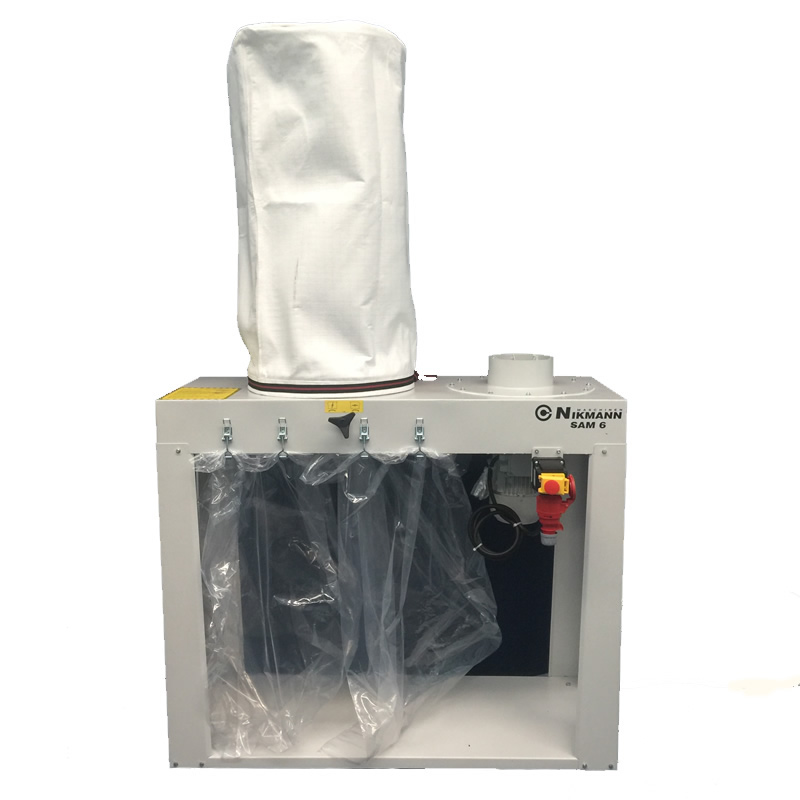

Dust and debris can accumulate on the saw, affecting its performance. Make it a habit to clean your saw after each use. Use a vacuum cleaner to remove sawdust and wipe down the surfaces with a damp cloth.

LUBRICATION

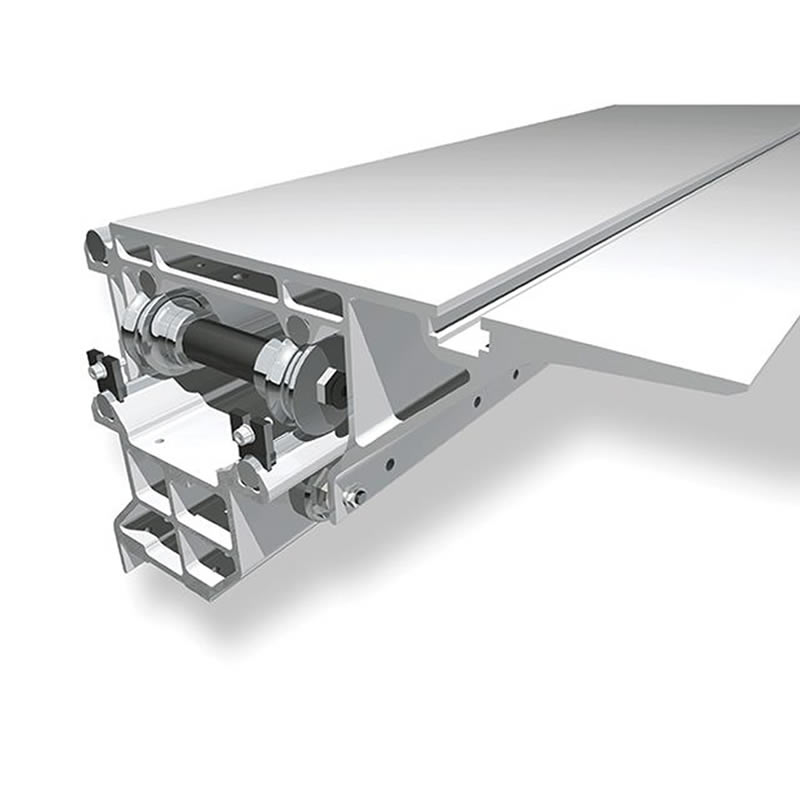

The sliding table mechanism needs regular lubrication to operate smoothly. Use a suitable lubricant and apply it to the sliding rails and other moving parts as recommended by the manufacturer.

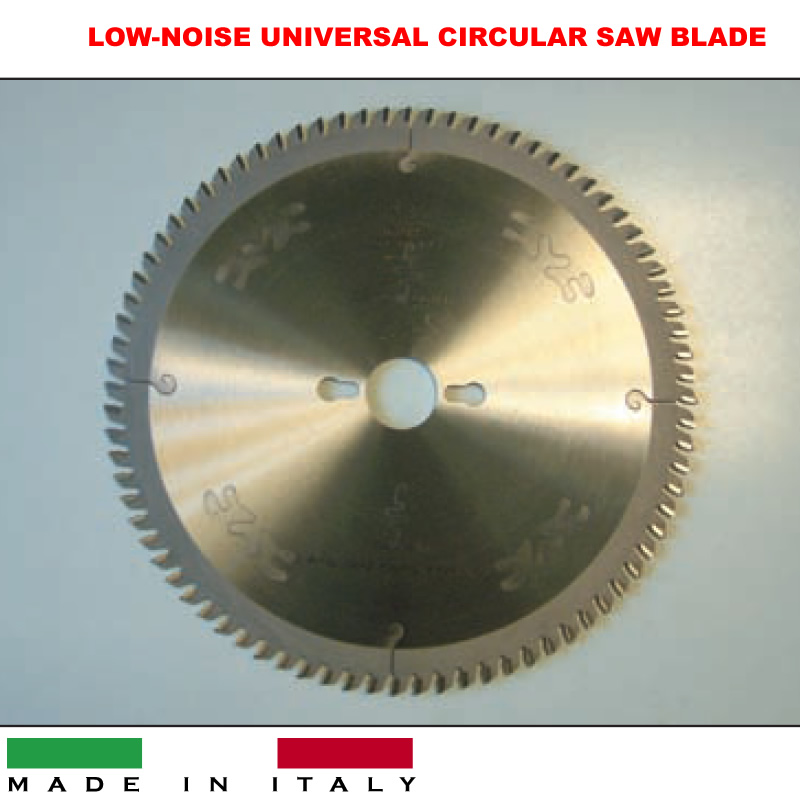

BLADE MAINTENANCE

The blade is the most critical component of your saw. Ensure it is always sharp and free from rust. Replace the blade if you notice any signs of wear or damage.

Automatic Panel Saw NikMann-S350-cnc

Price: $30,000.00 + GST

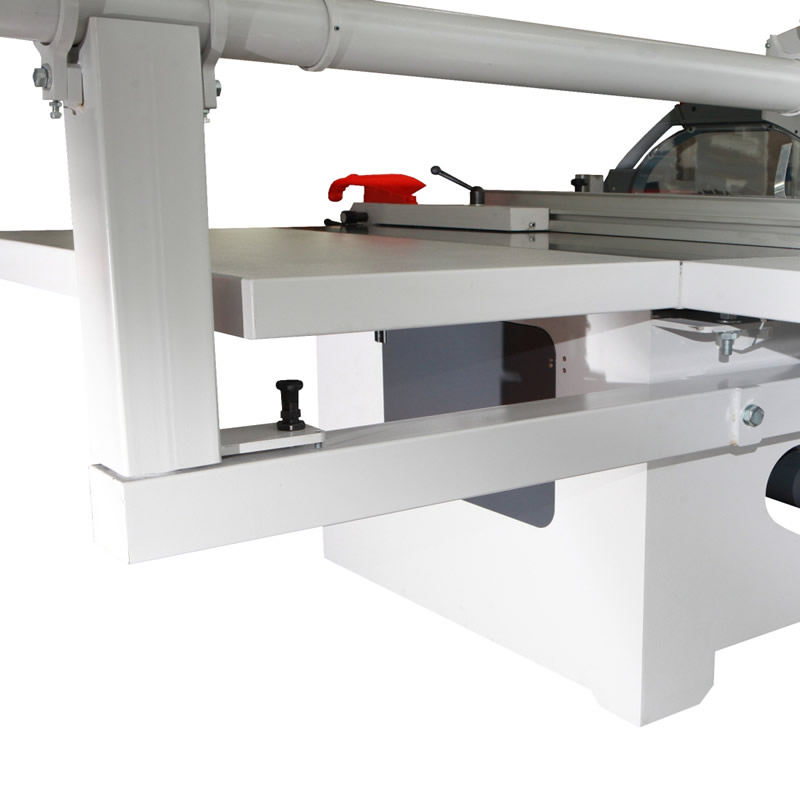

Heavy Duty sliding table panel saw with following machine configuration:

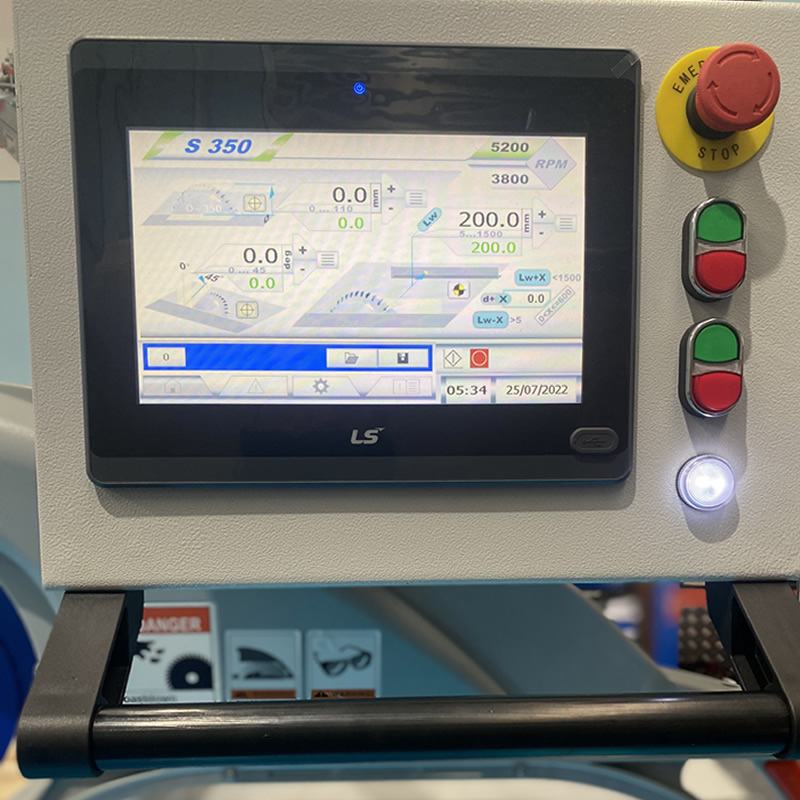

| Model: | NikMann S350-cnc |

| Sliding table length: | 3800 mm. |

| Sliding table width: | 400 mm. |

| Parallel fence width: | 1500 mm. |

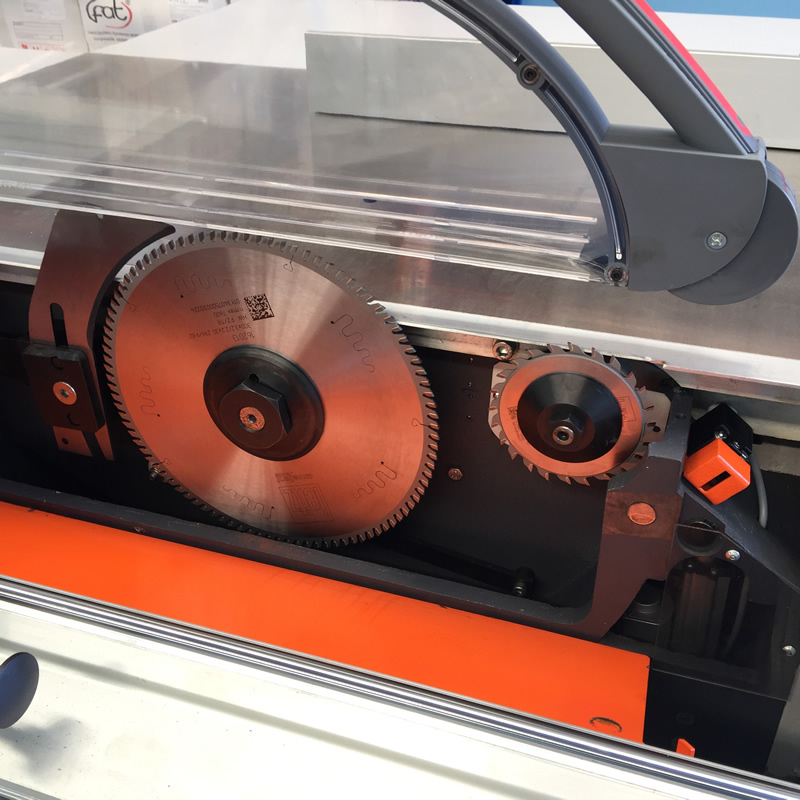

| Main saw blade diameter: | 300-350 mm |

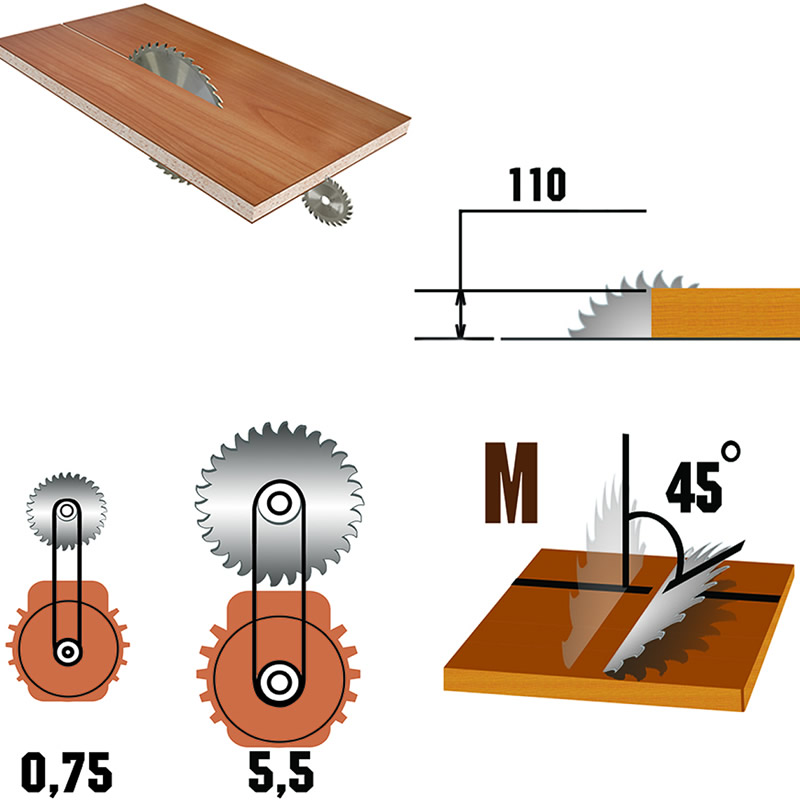

| Maximal height of cut to 0°: | 70-110 mm |

| Maximal height of cut to 45°: | 35-70 mm |

| Main saw blade speed: | 3800/5200 rpm |

| Main motor: | 5.5 Kw |

| Scoring saw blade diameter: | 120 mm |

| Scoring motor: | 1.1 Kw |

| Power: | 400 v. |

| Machine Dimensions: | 3800×3100×900 mm |

| For more information, please call: | 1300 4 FORZA |

Price excludes GST, Freight and Installation.