NikMann Spindle Moulders & Shapers – European Precision for Professional Woodworking

NikMann Spindle Moulders & Shapers are premium woodworking machines designed to deliver exceptional precision, power, and versatility in professional joinery, cabinetry, and timber processing environments. Manufactured in Europe and proudly offered across Australia by Forza Machinery, NikMann spindle moulders represent the perfect blend of traditional craftsmanship and modern engineering. They are ideal for high-volume workshops, custom furniture makers, and timber professionals seeking reliable, heavy-duty shaping solutions.

A spindle moulder, also known as a shaper, is a vital piece of equipment in any serious woodworking shop. It is primarily used for profiling, tenoning, grooving, rebating, and edge shaping, allowing the user to create complex mouldings and joinery components with ease and repeatable accuracy. NikMann Spindle Moulders are built to handle these demanding applications with consistent performance and durability.

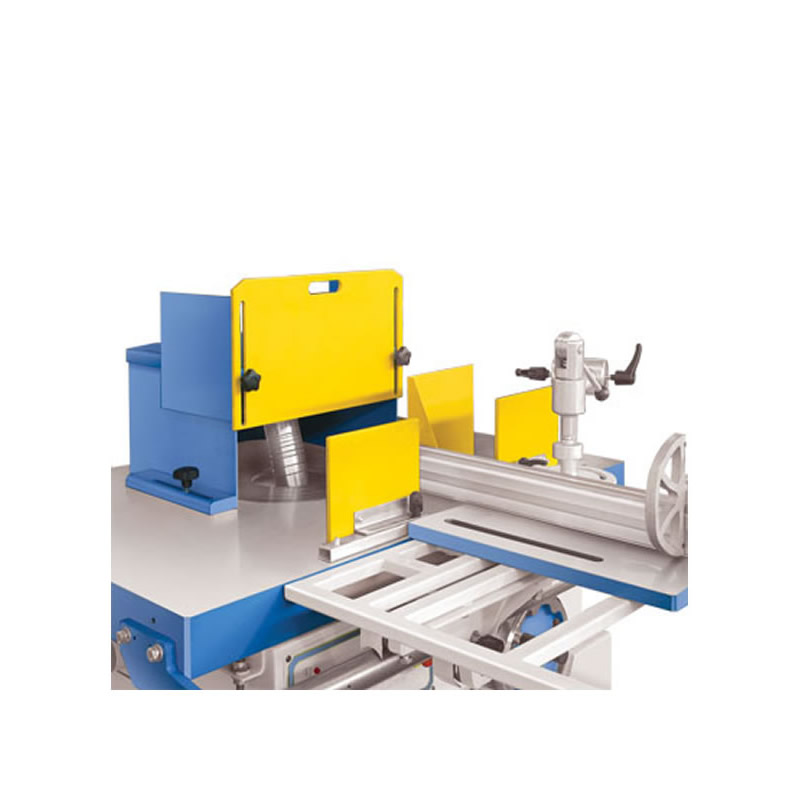

Our shapers are the product of continuing in-house development using the finest skills and "Know How" available. The frames are particularly well-made and designed to reduce vibrations, the enemy of all quality machines. This produces a perfectly trimmed panel edge every time. NikMann machines are compact and solid built for your specific processing needs.

At the core of every NikMann spindle moulder is a high-torque industrial motor—usually ranging from 5.5 kW to 11 kW depending on the model—which drives the spindle at high speed for smooth, clean cutting. The machines typically feature variable spindle speeds (from around 3,000 to 10,000 RPM), allowing the operator to adjust the speed to match the type of cutter and material being used. This flexibility ensures optimal results whether working with hardwood, softwood, or composite panels.

One of the standout features of NikMann spindle moulders is the interchangeable spindle system, which allows for fast setup changes and increases versatility in tooling options. Many models offer both fixed and tilting spindles (±45°), which significantly expand the range of possible profiles and joint configurations. This makes them ideal for everything from simple edge shaping to advanced joinery and custom profiles.

Safety is a major priority in the design of NikMann spindle moulders. These machines are equipped with adjustable safety fences, tool guards, spindle brakes, and electronic overload protection to ensure secure operation at all times. The solid cast-iron table surface and vibration-dampening frame construction contribute to a smooth, stable performance that minimises operator fatigue and increases accuracy.

Spindle Moulders and Shapers NikMann Series

Key Features to Consider

When buying spindle moulders and shapers, certain features are important. These features can greatly affect the machine's performance and your woodworking results. Power and precision are key. A powerful machine ensures efficient cutting, while precision guarantees accurate results. Safety features are also crucial. Look for machines with safety guards and emergency stop buttons.

Here are some key features to consider:

- Power and precision;

- Safety features;

- Machine versatility;

- Size and capacity;

- Dust extraction systems;

- Speed settings;

- Compatibility with existing equipment;

- Compliance with safety standards;

NikMann spindle moulders stand out in the Australian market. They are known for their quality and reliability. These machines offer high power and precision. They are perfect for both professional and hobbyist woodworkers.

NikMann also offers custom configurations. This allows you to tailor the machine to your specific needs. Choosing NikMann means investing in a machine that delivers excellent results. It's a choice many Australian woodworkers make.

Making the Right Choice for Your Woodworking Needs