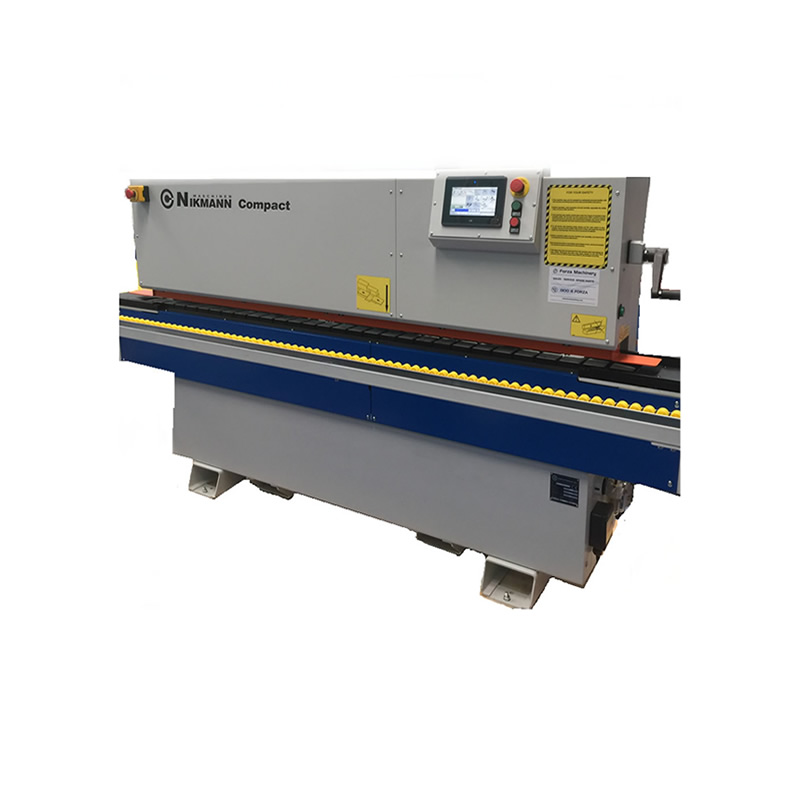

NikMann-TF Edgebander with Pre-Milling: Built for Precision and Professional Results

The NikMann-TF edgebander with a pre-milling station is a high-performance, industrial-grade edge banding machine engineered for woodworking professionals who demand accuracy, reliability, and premium finishing. Manufactured in Europe to the strictest standards and supported in Australia by Forza Machinery, the NikMann-TF is built to deliver consistent results across high-volume operations—whether you're producing flat-pack kitchens, office furniture, wardrobes, or custom cabinetry.

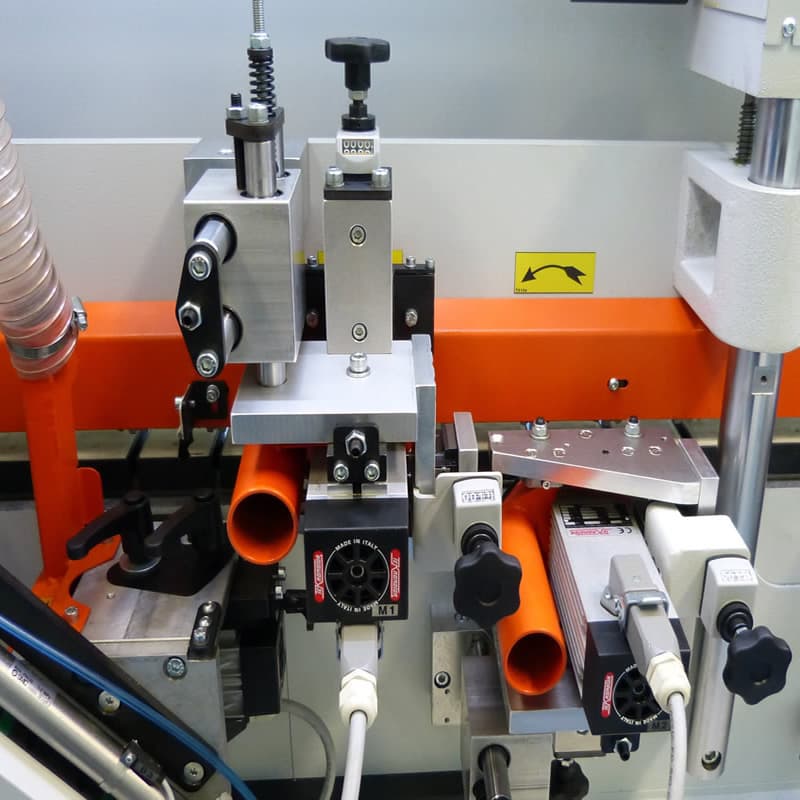

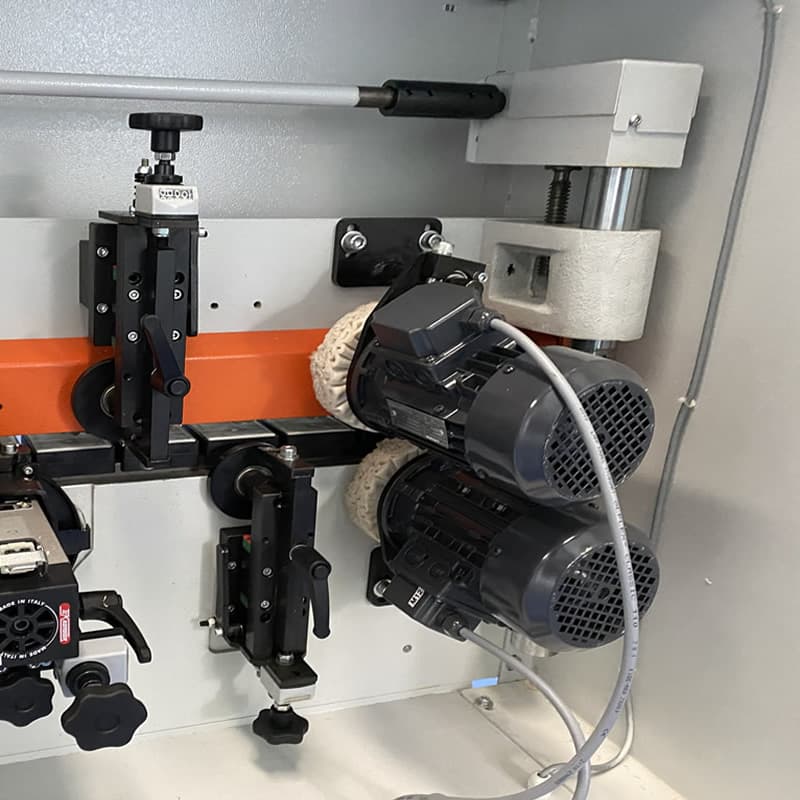

What sets the NikMann-TF apart from standard edgebanders is its integrated pre-milling unit. This feature allows the machine to trim a thin layer from the panel’s edge before the glue and tape are applied. Pre-milling is essential for removing chips, uneven surfaces, and manufacturing tolerances commonly found on raw or laminated boards. It ensures that the edge is perfectly straight and clean, improving adhesive bonding and producing a seamless, factory-quality finish—especially noticeable on high-gloss or matte panels.

The pre-milling station uses diamond-tipped cutter heads, which provide an extended service life and deliver clean, accurate cuts even on tough materials such as MDF, particle board, and laminated surfaces. This significantly reduces the need for hand-finishing or reworking, saving valuable production time and increasing the quality of your finished product.

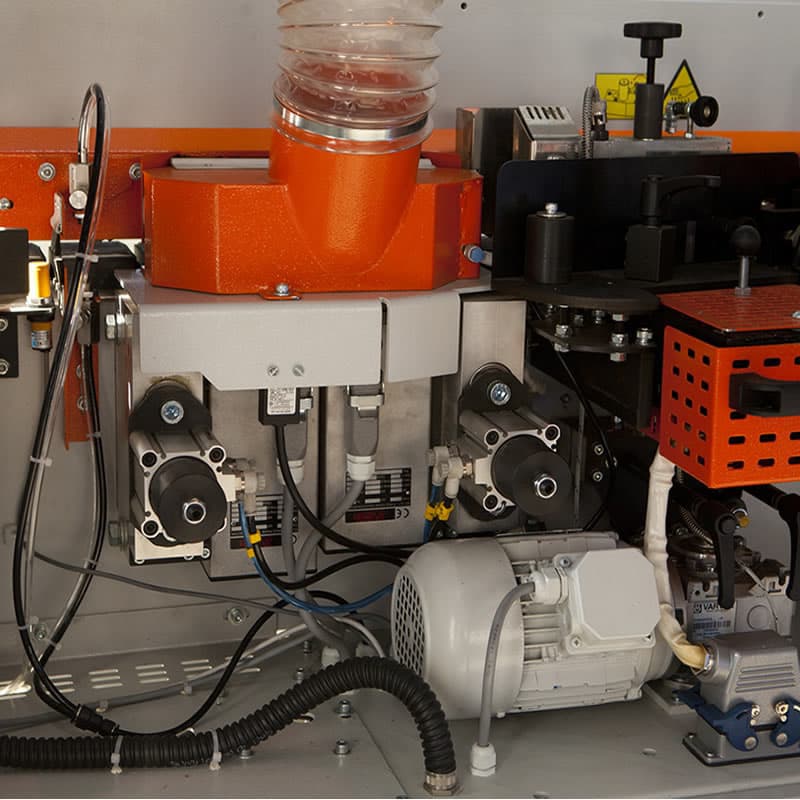

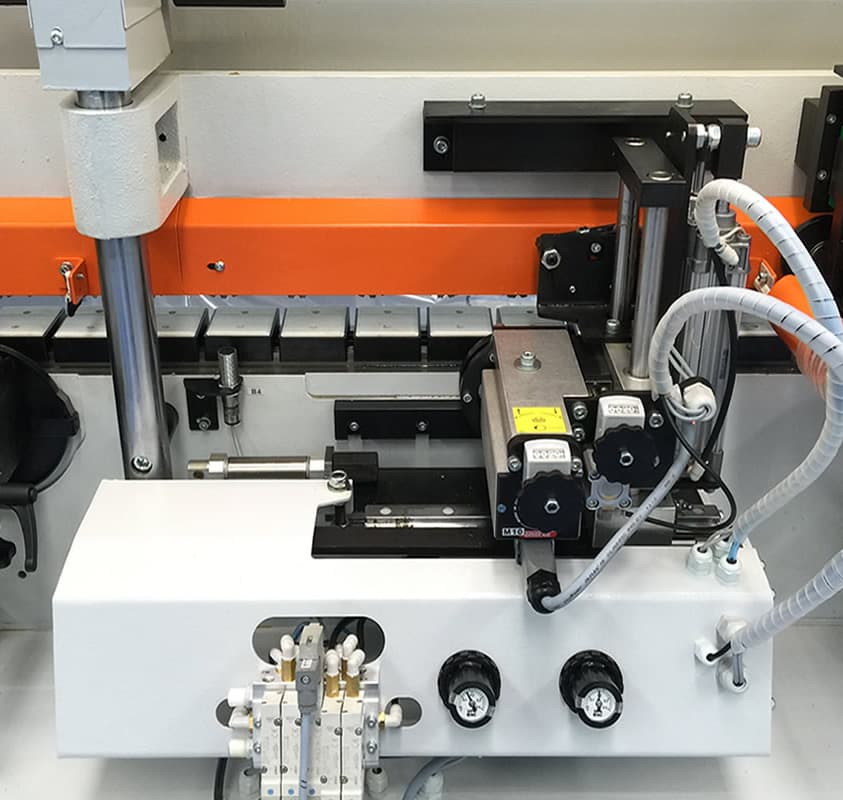

The glue application system in the NikMann-TF is designed to work with EVA adhesive and features a Teflon-coated glue pot for easy cleaning and smooth glue distribution. The glue pot ensures fast heat-up and consistent temperature control, crucial for strong bonding. The machine feeds edge material automatically—whether it’s PVC, ABS, wood veneer, or melamine tape—cutting it to length and applying it under pressure with precision rollers that ensure a strong and even bond.

With reliable local service and support from Forza Machinery Australia, the NikMann-TF edgebander offers unbeatable value for businesses aiming to grow their production while maintaining high standards. Whether you're a growing cabinet shop or a full-scale furniture manufacturer, the NikMann-TF with pre-milling is a wise investment that enhances quality, efficiency, and customer satisfaction.

Edge bander NikMann-TF

Price: $45,000.00 + GST

Heavy Duty hot melt, single-sided edgebander with:

- Pre-milling Station with diamond blades;

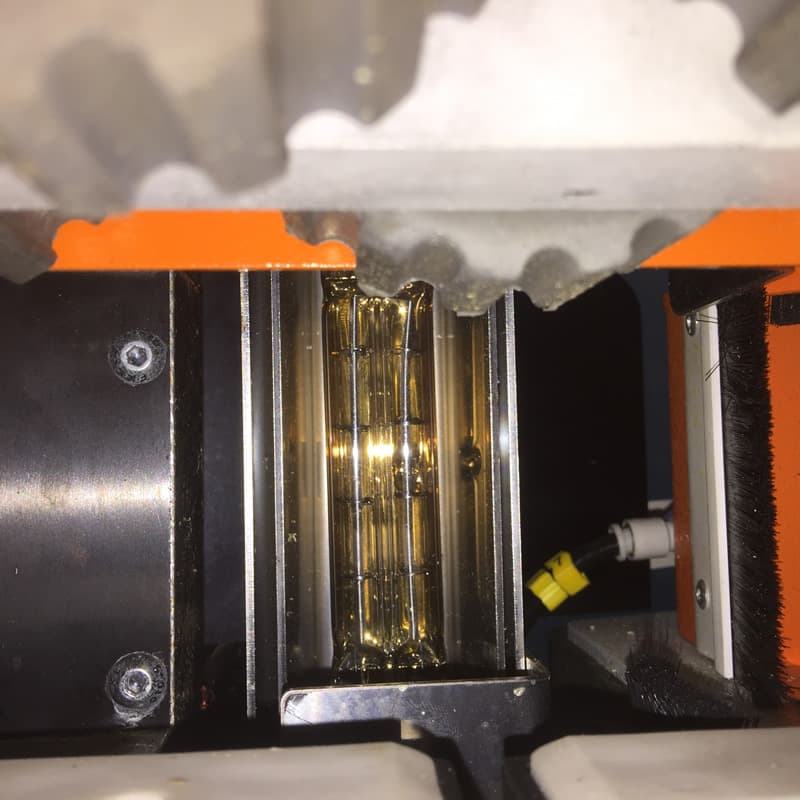

- Infrared Light to pre heat the panel in a winter;

- Easy to set and Quick change Teflon glue tank;

- Three independent pressure rollers controlled by air pressure;

- Two End Saws;

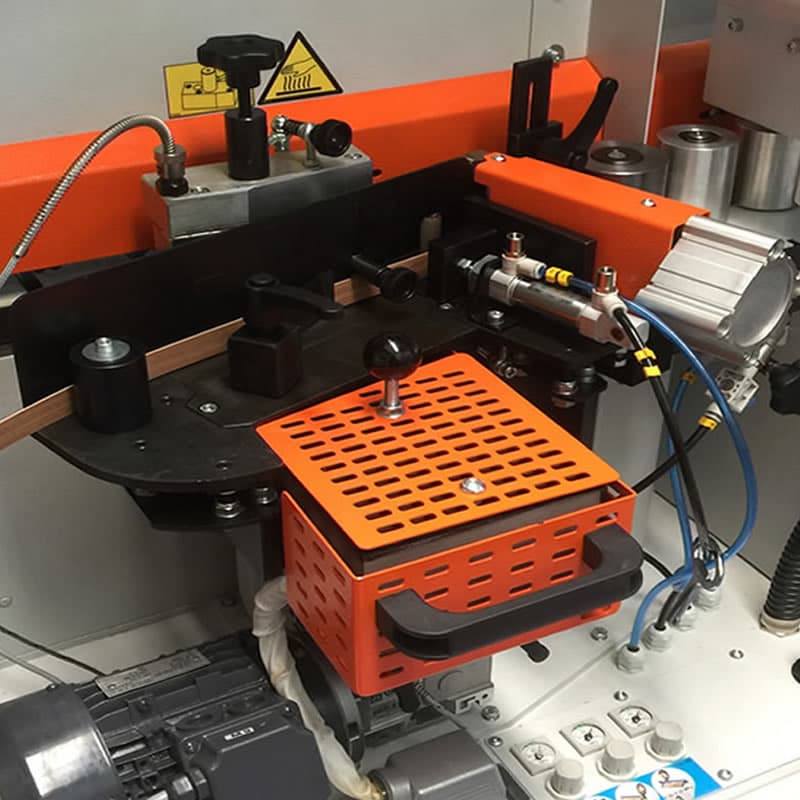

- Top and Bottom Fine Trimming station equipped with a Nesting Kit for doors;

- Round Scrapers equipped with a Nesting Kit for doors;

- Glue Scrapers equipped with a Nesting Kit for doors;

- Top and Bottom Buffers;

- Dimensions: 3420 × 1220 × 1470 mm;

- Panel Length: ≥100 mm;

- Panel Thickness: 10~60 mm;

- Feed Speed: 10 m/min;

- User-friendly Touch Screen;

- Efficient high frequency inverters on motors for saws and trimmers;

- Italian made VarVel gear box with longlife lubrication;

- Italian made HF motors by TeknoMotors;

Price includes Delivery, Installation and Training.