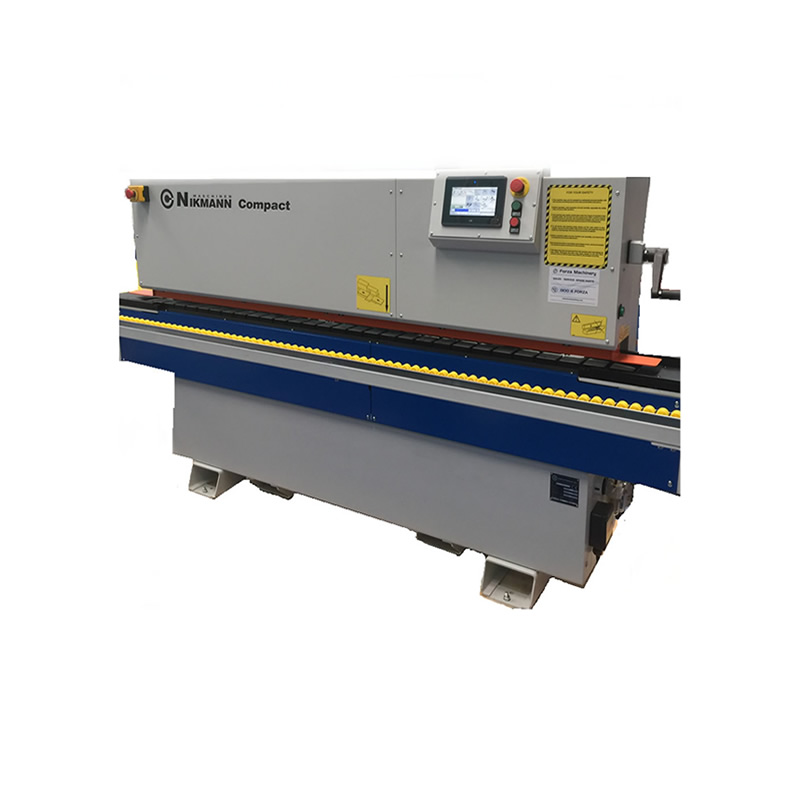

NikMann-RTF Edgebander: Precision, Power, and Performance

The NikMann-RTF edgebander is a robust, industrial-grade machine designed for professional cabinet makers, furniture manufacturers, and high-volume woodworking shops that demand precision and efficiency. Engineered in Europe and tailored to meet the rigorous requirements of the Australian woodworking industry, the NikMann-RTF stands out with its advanced automation, consistent output quality, and durability over long production runs.

At its core, the NikMann-RTF is designed to handle a wide variety of edge banding tasks with speed and precision. Whether you're working with PVC, ABS, melamine, wood veneer, or solid timber edging, this machine provides flawless application and finishing. It features a Teflon-coated glue pot, capable of handling EVA and PUR adhesives, which ensures strong, reliable bonds with excellent heat and water resistance—perfect for kitchen, bathroom, and commercial furniture.

The machine is equipped with pre-milling units, which prepare the panel edges by removing imperfections and ensuring a clean, flat surface before the tape is applied. This step alone significantly improves the bonding surface and the overall finish, especially when working with laminated or chipboard panels that may have chipping or uneven edges.

The NikMann-RTF includes automatic edge feeding, precision pressure rollers, and heavy-duty top and bottom trimming units to ensure the tape is pressed evenly and excess material is cleanly removed. The inclusion of corner rounding units makes this model ideal for manufacturers who require seamless edges even on curved or contoured panels—a task that traditionally required manual finishing.

Why Choose the NikMann-RTF?

The NikMann-RTF edgebander, strikes an ideal balance between cost-efficiency and production-grade capability. Its user-friendly interface, robust construction, and low-maintenance design make it an excellent choice for growing workshops and production facilities alike. With an emphasis on reliability and accuracy, the RTF is built to deliver consistent performance for years.

Discover the performance of the NikMann-RTF Edgebander—available now through Forza Machinery, Australia’s trusted supplier of European woodworking equipment.

Edgebander NikMann-RTF

Price: $55,000.00 + GST

Heavy Duty hot melt, single-sided edgebander with:

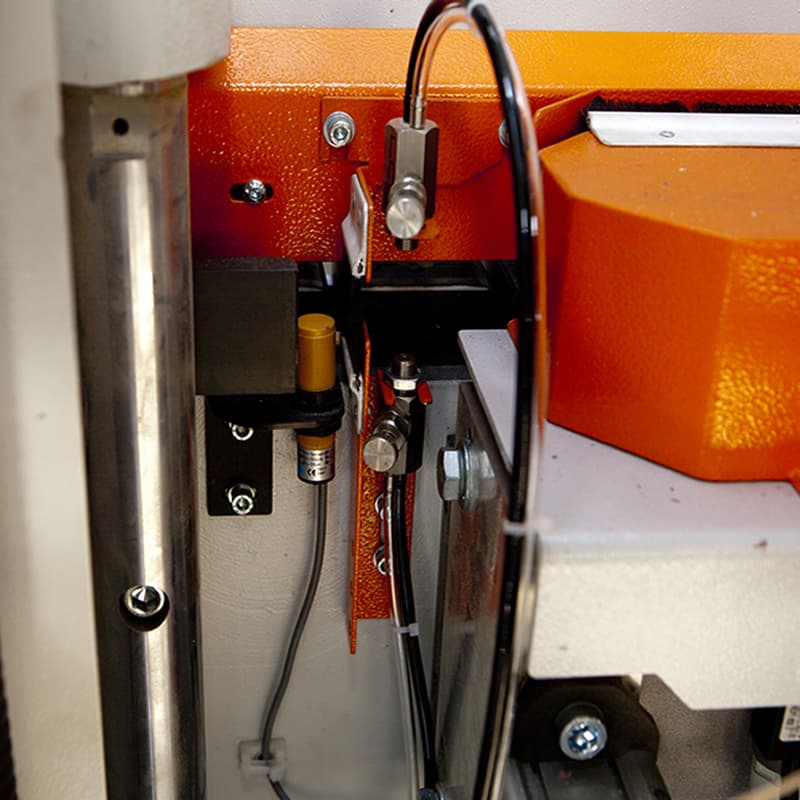

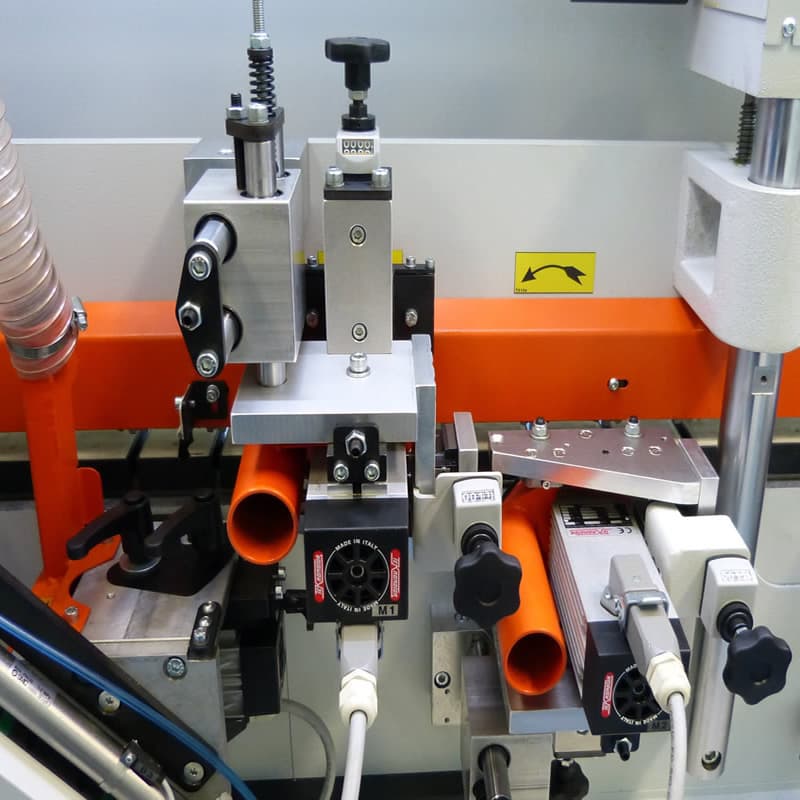

- Front Spray Station;

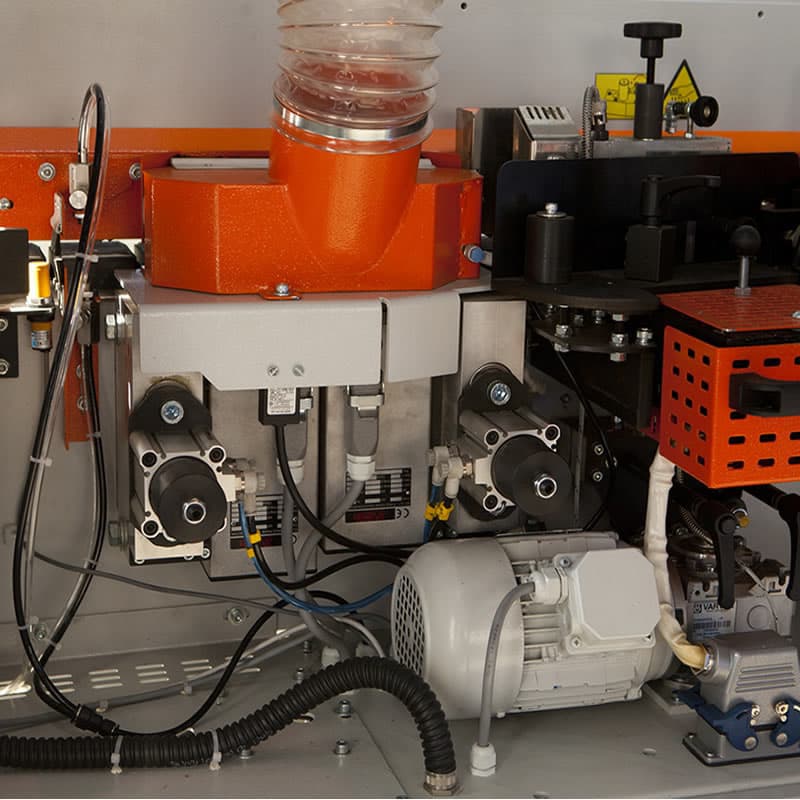

- Pre-milling Station with diamond blades;

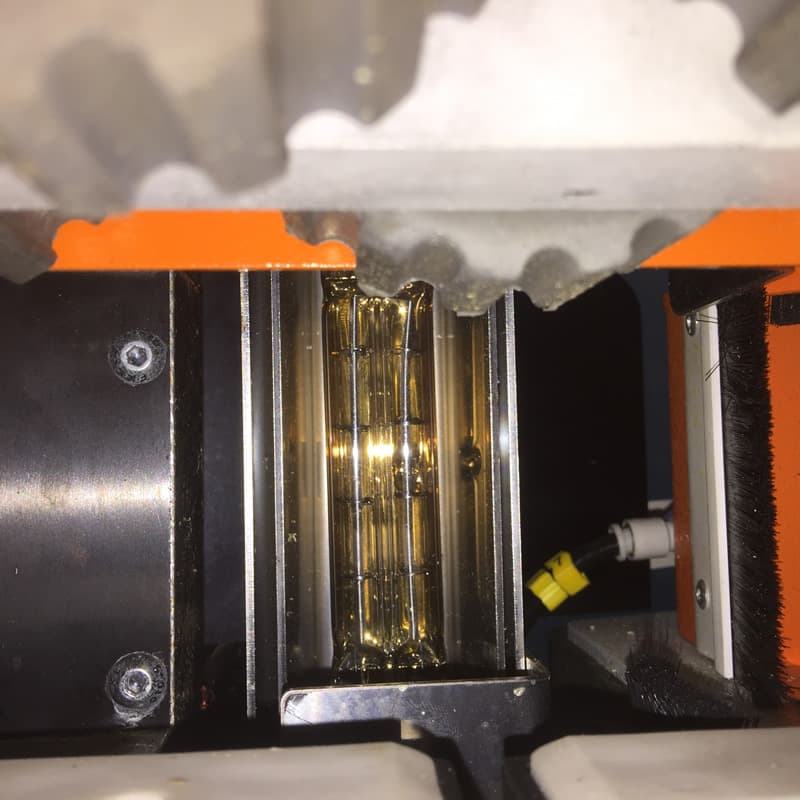

- Infrared Light to pre heat the panel in a winter;

- Easy to set and Quick change Teflon glue tank;

- Three independent pressure rollers controlled by air pressure;

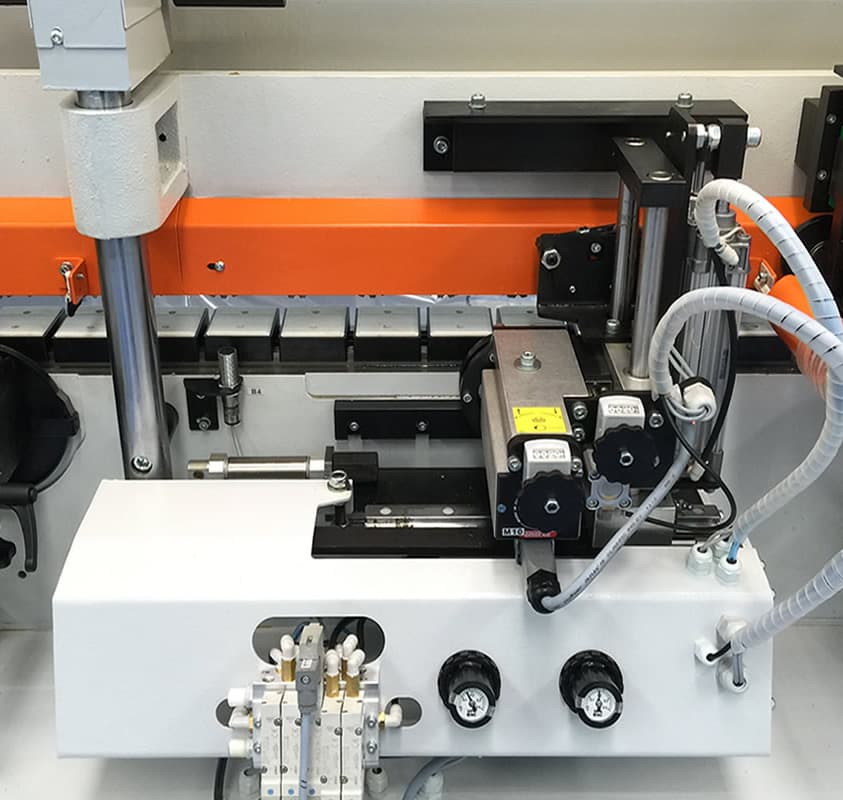

- Two End Saws;

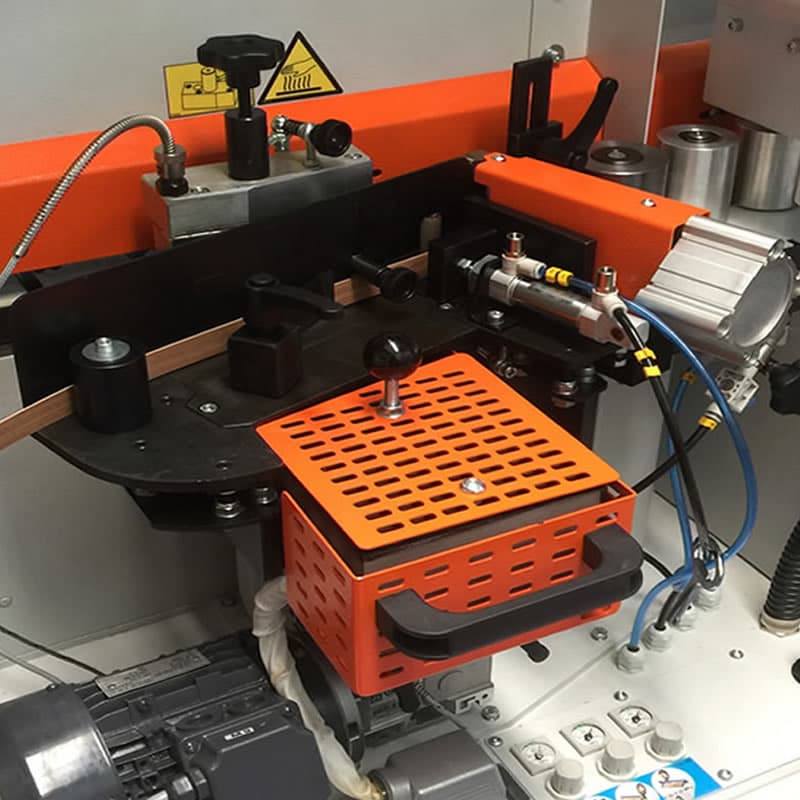

- Top and Bottom Fine Trimming station equipped with a Nesting Kit for doors;

- Corner Rounder;

- Round Scrapers equipped with a Nesting Kit for doors;

- Glue Scrapers equipped with a Nesting Kit for doors;

- Back Spray Station;

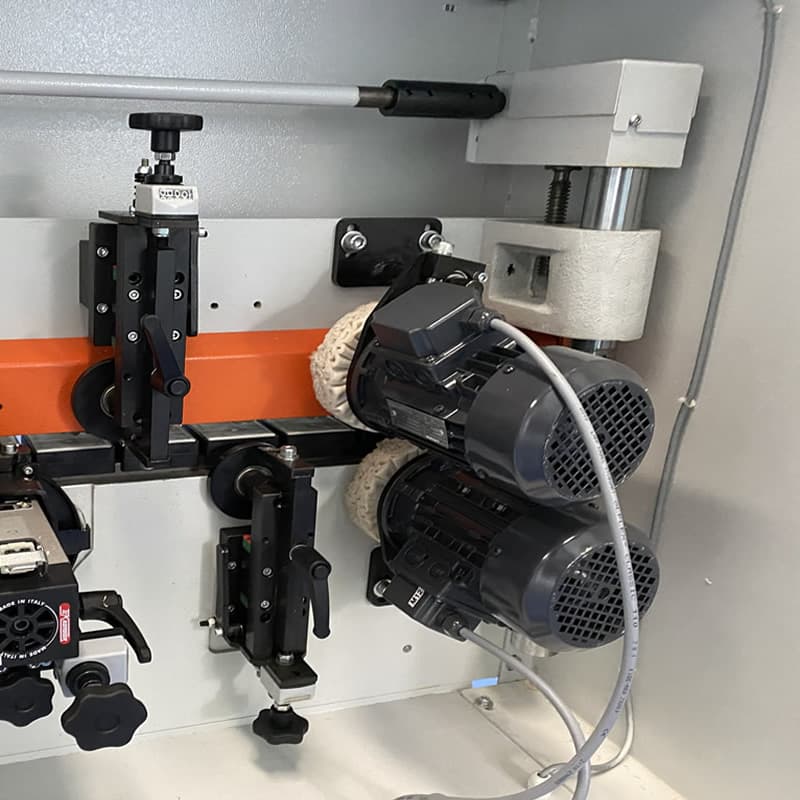

- Top and Bottom Buffers;

- Dimensions: 5500 × 1440 × 1730 mm;

- Panel Length: ≥100 mm;

- Panel Thickness: 10~60 mm;

- Feed Speed: 12 - 18 m/min;

- User-friendly Touch Screen;

- Efficient high frequency inverters on motors for saws and trimmers;

- Italian made VarVel gear box with longlife lubrication;

- Italian made HF motors by TeknoMotors;

- Return Conveyor - OPTIONAL;

Price includes Delivery, Installation and Training.