Edge Bander with PUR glue for durable edge banding

Edge banders using PUR (polyurethane) glue are specialized machines used to apply a durable edge banding to the edges of panels, such as those made from MDF or particle board. PUR glue is preferred in many applications due to its strong bonding capabilities and moisture resistance, making it ideal for high-quality and long-lasting edge finishing.

Edgebanders and edge banding machines are essential tools in woodworking, particularly for creating smooth, finished edges on panels and boards.

Machines typically use a hot-melt adhesive to attach the edging strips. The machine applies the adhesive to the board’s edge, then presses the edging material onto it, creating a seamless finish

Sale | Service | Spare Parts

Our edge banding machines are engineered for minimal setup and maximum flexibility, accommodating a wide range of edge banding units. With various models available, you can choose the perfect configuration with essential working units such as pre-milling, corner rounding, radius scraping, and more—ensuring a flawless finished edge.

The demand for edgebanders and edge banding machines has never been greater. With a vast selection of panel types and finishes available, choosing the right edgebander is crucial to achieving the perfect aesthetic for your case goods and cabinet doors.

When choosing an edge bander, assess your production needs, the volume of work, and budget. For high-quality, durable finishes, investing in a machine with a good PUR glue system can be well worth it.

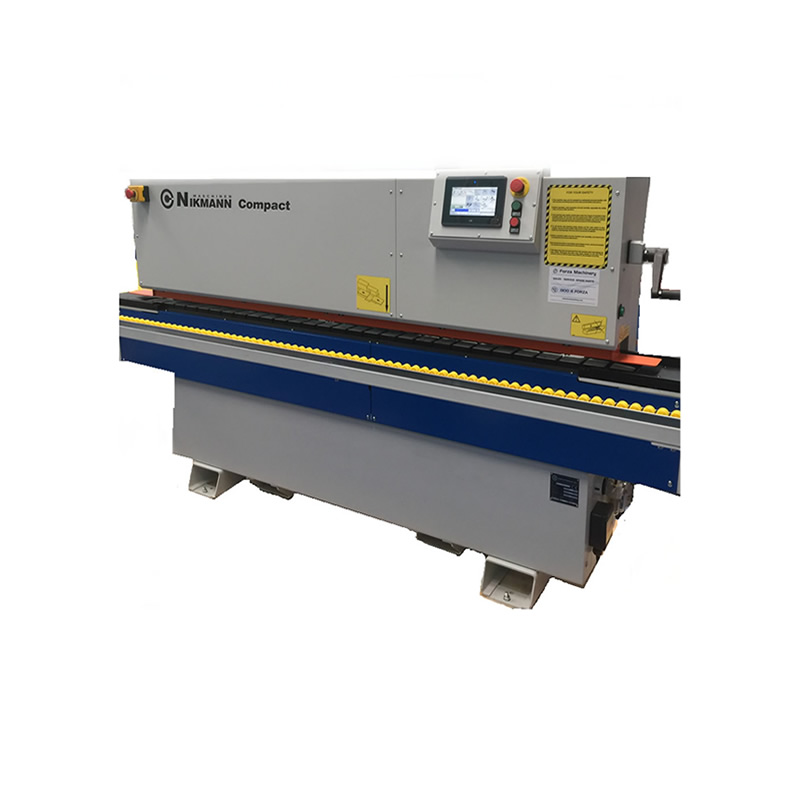

Edge Bander NikMann-PUR

Price: $85,000.00 + GST

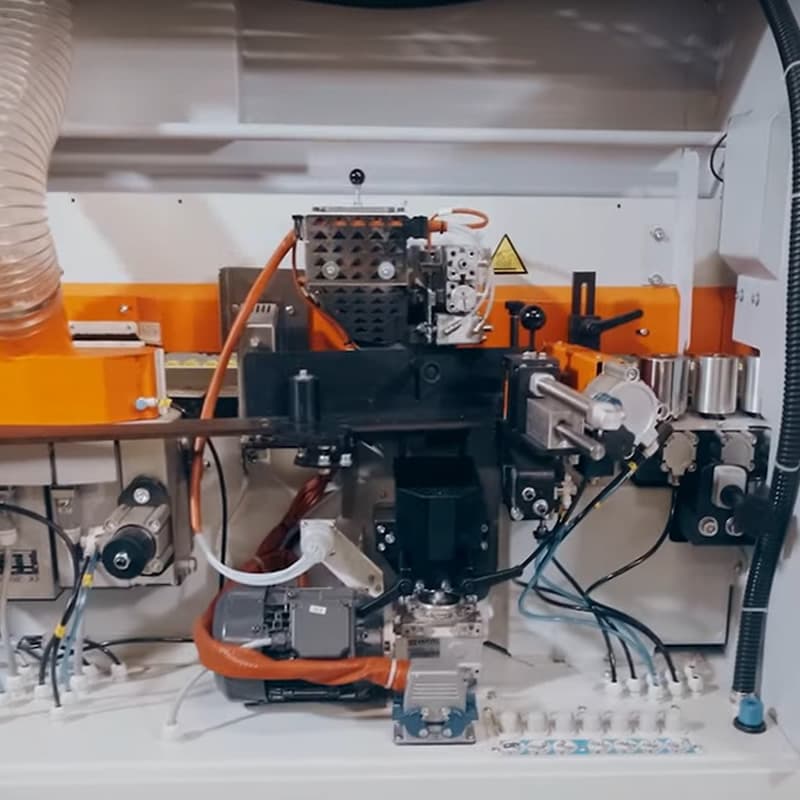

Heavy Duty hot melt, single-sided edge bander with:

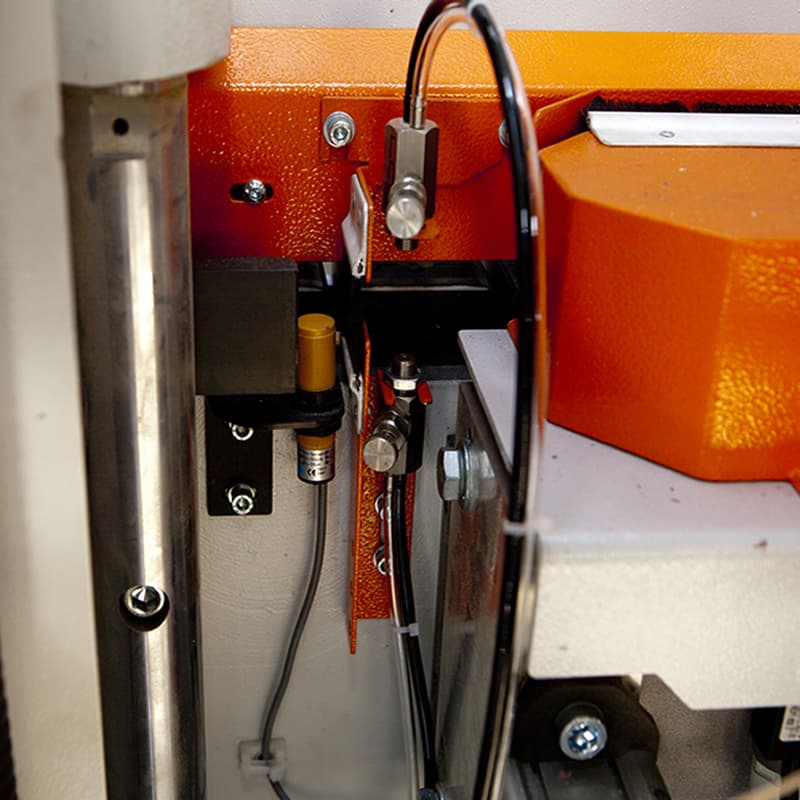

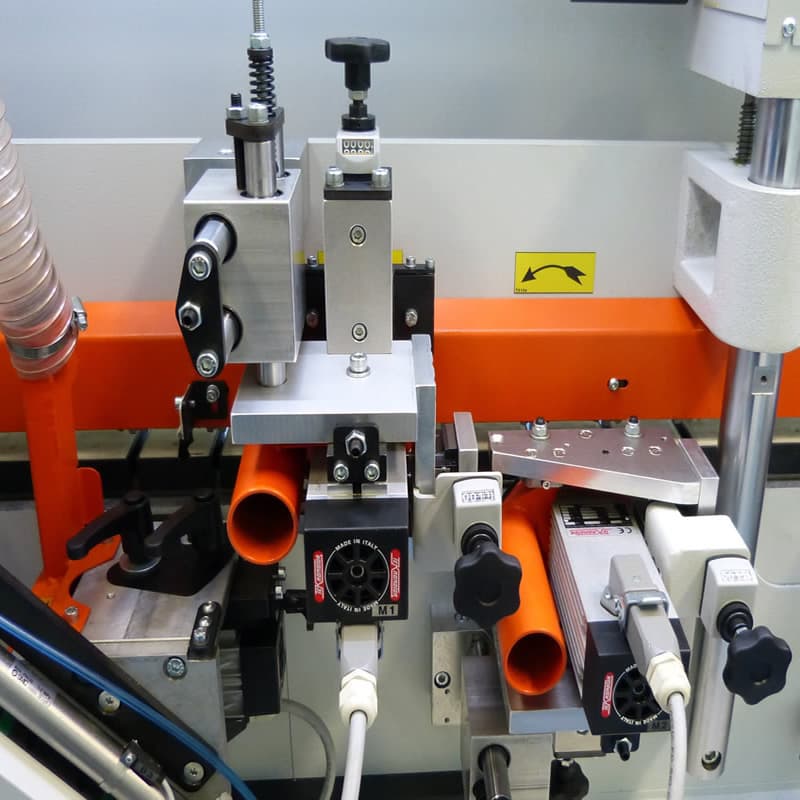

- Front Spray Station;

- Pre-milling Station with diamond blades;

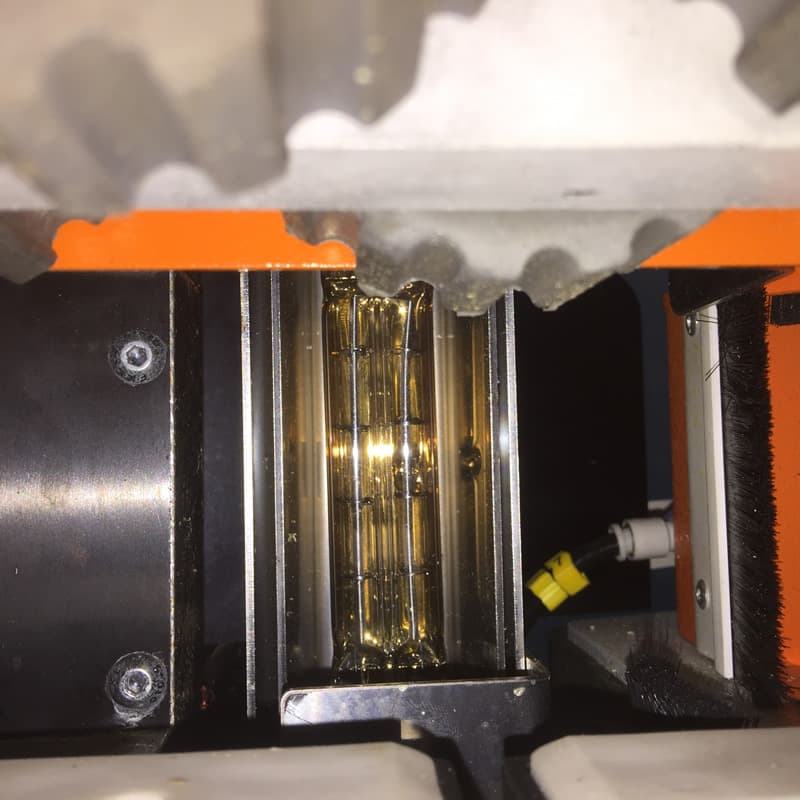

- Infrared Light to pre heat the panel in a winter;

- Easy to set and Quick change PUR glue tank;

- Three independent pressure rollers controlled by air pressure;

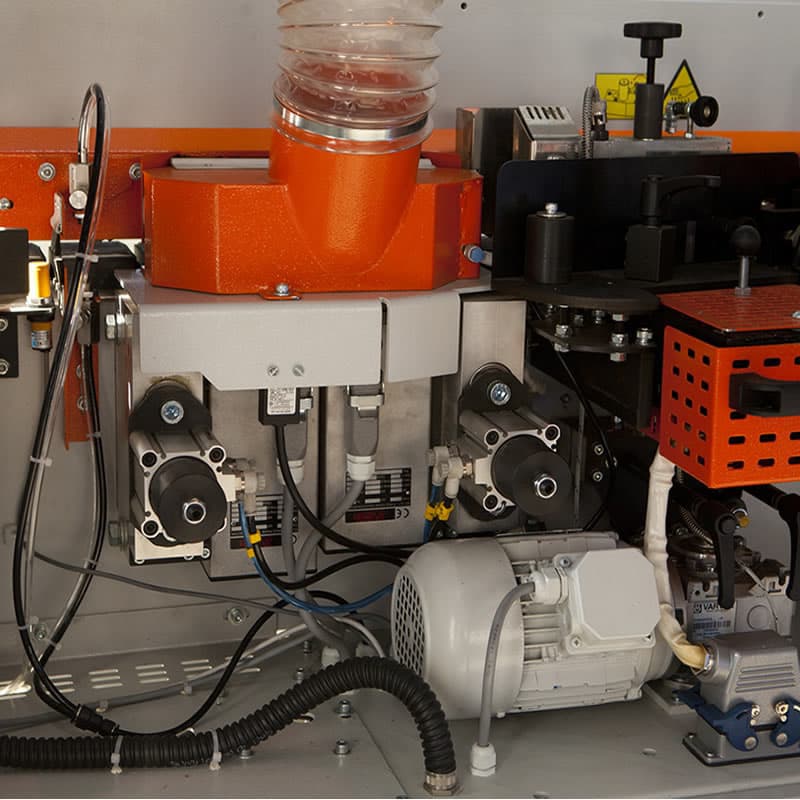

- Two End Saws;

- Top and Bottom Fine Trimming station equipped with a Nesting Kit for doors;

- Twin Corner Rounders for faster trimming;

- Round Scrapers equipped with a Nesting Kit for doors;

- Glue Scrapers equipped with a Nesting Kit for doors;

- Back Spray Station;

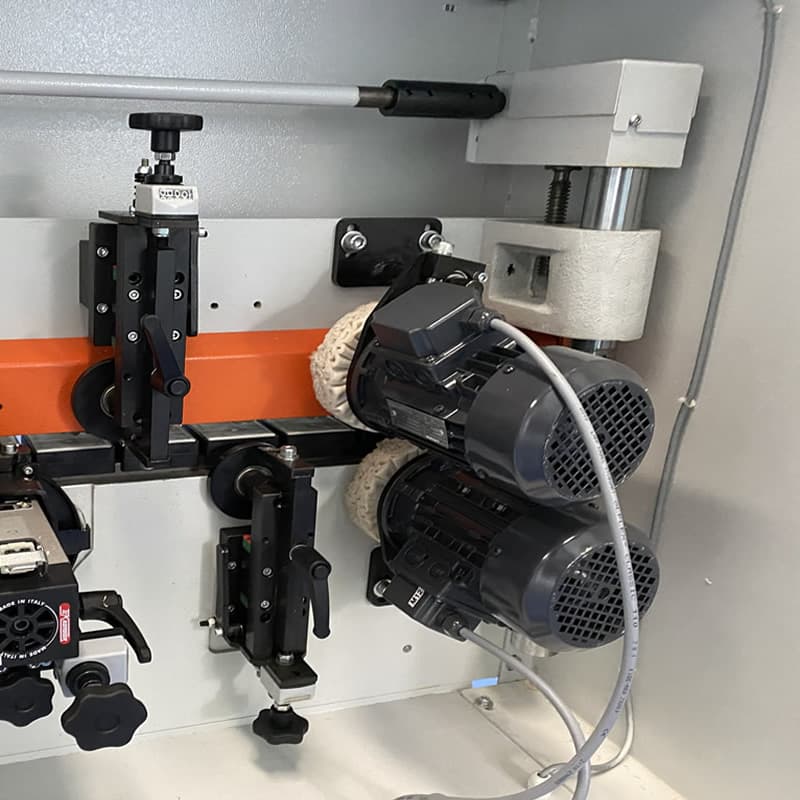

- Top and Bottom Buffers;

- Dimensions: 5500 × 1440 × 1730 mm;

- Panel Length: ≥100 mm;

- Panel Thickness: 10~60 mm;

- Feed Speed: 12 - 18 m/min;

- User-friendly Touch Screen;

- Efficient high frequency inverters on motors for saws and trimmers;

- Italian made VarVel gear box with longlife lubrication;

- Italian made HF motors by TeknoMotors;

- Return Conveyor - OPTIONAL;

Price excludes GST, Freight and Installation.