Sale | Service | Spare Parts

Edge banding machines NikMann-Contour are used in woodworking to apply a strip of material (known as edge banding) to the edges of panels or boards. This process not only improves the appearance of the panel but also provides protection against moisture and wear.

Picking the perfect edge banding machine hinges on your production output, the materials you handle, and the degree of automation you need. If you’d like tailored suggestions or more detailed information, I’m here to help!

Machines are compatible with a variety of materials, including PVC, ABS, veneer, and more. Always confirm that the machine you select is suited to the specific material you intend to work with.

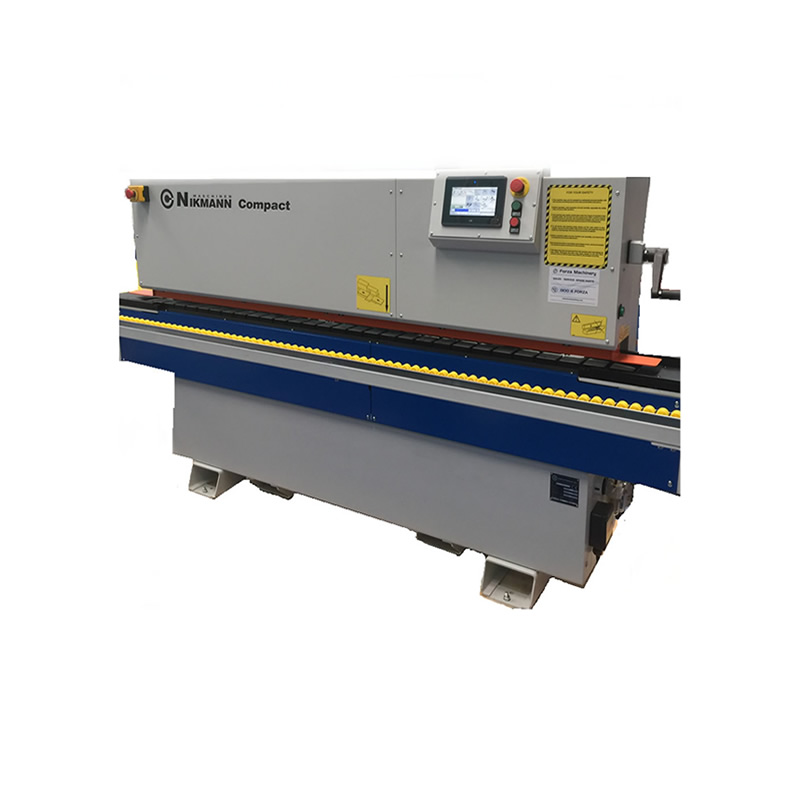

Edgebander NikMann-Contour

$10,000.00

If you’re looking for specific edgebander models, NikMann Machinery offer machine with features suited for various applications, including curved panels and 45 degrees edging.

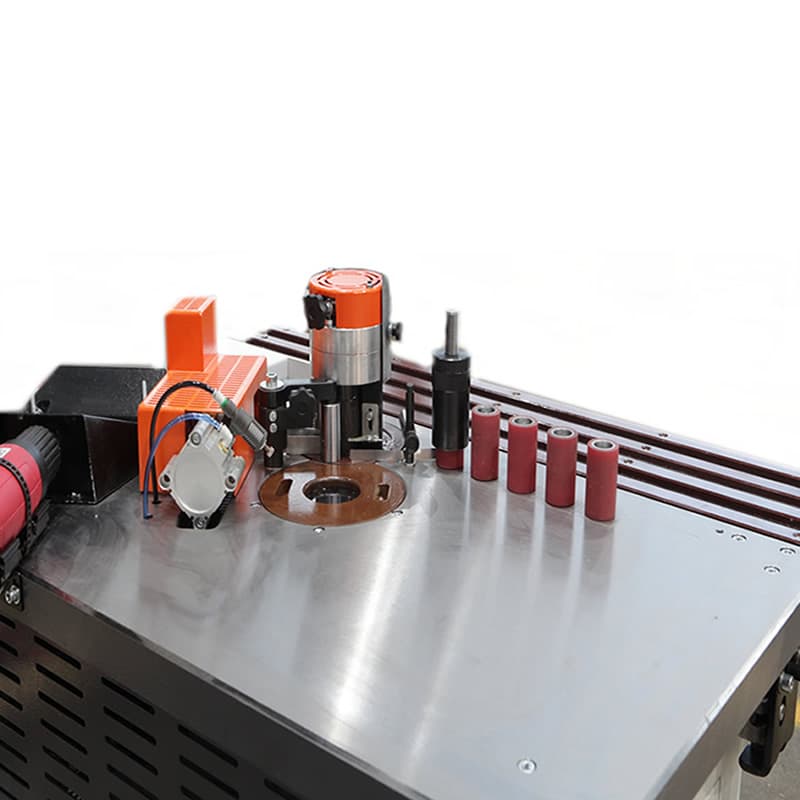

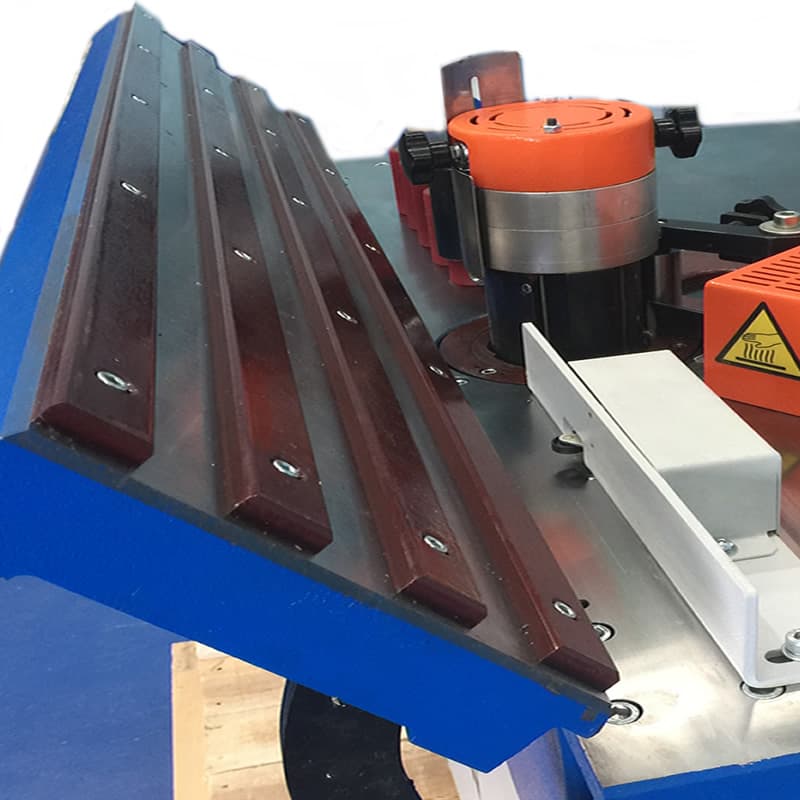

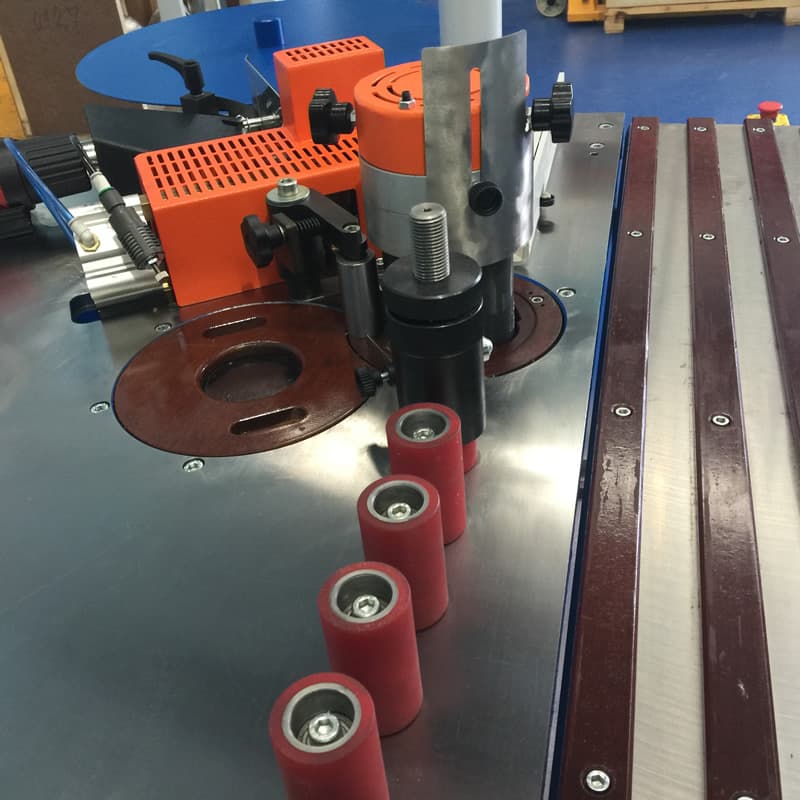

Heavy Duty hot melt, single-sided edgebander for curved panels and 45 degrees with:

- Thickness of the edge - 0.4 to 3 mm;

- Min/Max. height of the panel - 10 to 50 mm;

- Minimal radius of curvature - 20 deg.;

- Tilting of the working table - 0-45 deg.;

- Feeding speed - 0-8 m/min;

- Heating temperature - 0-250 C;

- Total installed capacity - 2.75 kW;

- Power supply voltage - 220v AC, 50Hz;

- Working air pressure, - 6.5 bar;

- Overall dimension - 1924 х 1080 x 1446 mm;

- Weight - 300 kg;

Price excludes GST, Freight and Installation.