Edge Bander With Pre Milling and Corner Rounding

Our edgebanding machines are designed to minimize setup while allowing for wide flexibility of edge banding applications. We have a wide range of models to choose from with the working units you need for your application, including pre-milling, corner rounding, radius scraping, and more, which are used to produce the optimum finished edge.

Today, the demands on edgebanders have never been higher. And with such a wide array of panel types and finishes available on the market today, you need the right edgebander to ensure the optimum esthetic of your case goods and cabinet doors.

Sale | Service | Spare Parts

Edge banding machines NikMann-2RTF are used in woodworking to apply a strip of material (known as edge banding) to the edges of panels or boards. This process not only improves the appearance of the panel but also provides protection against moisture and wear.

Choosing the right edge banding machine depends on your production volume, the materials you use, and the level of automation you require. If you're looking for recommendations or specifics, I can help with that too!

Machines can handle various materials including PVC, ABS, veneer, and more. Ensure the machine you choose supports the material you plan to use.

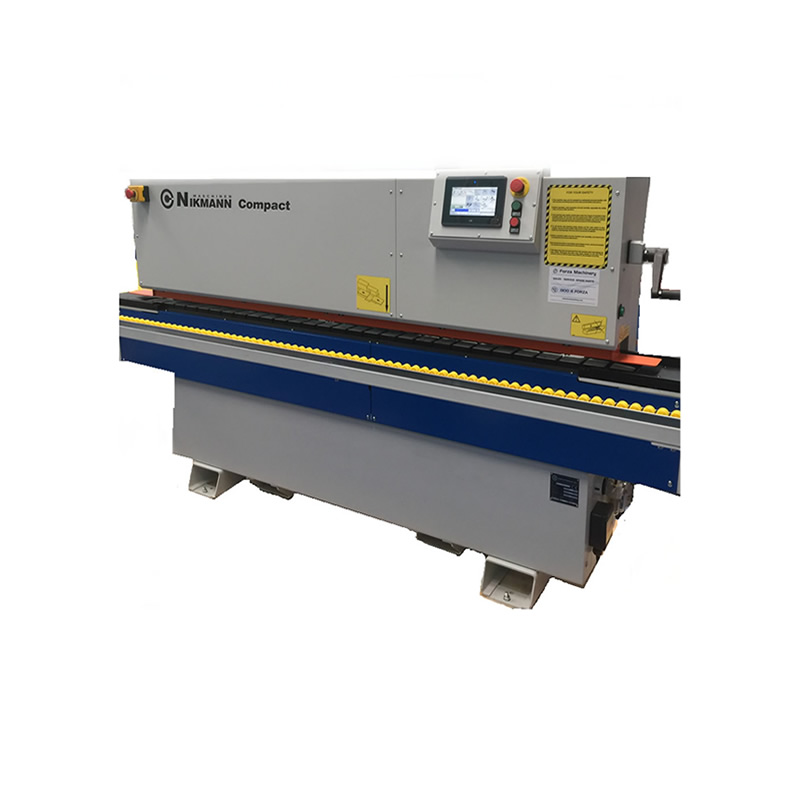

Edgebander NikMann 2RTF

Price: $65,000.00 + GST

Heavy Duty hot melt, single-sided edgebander with:

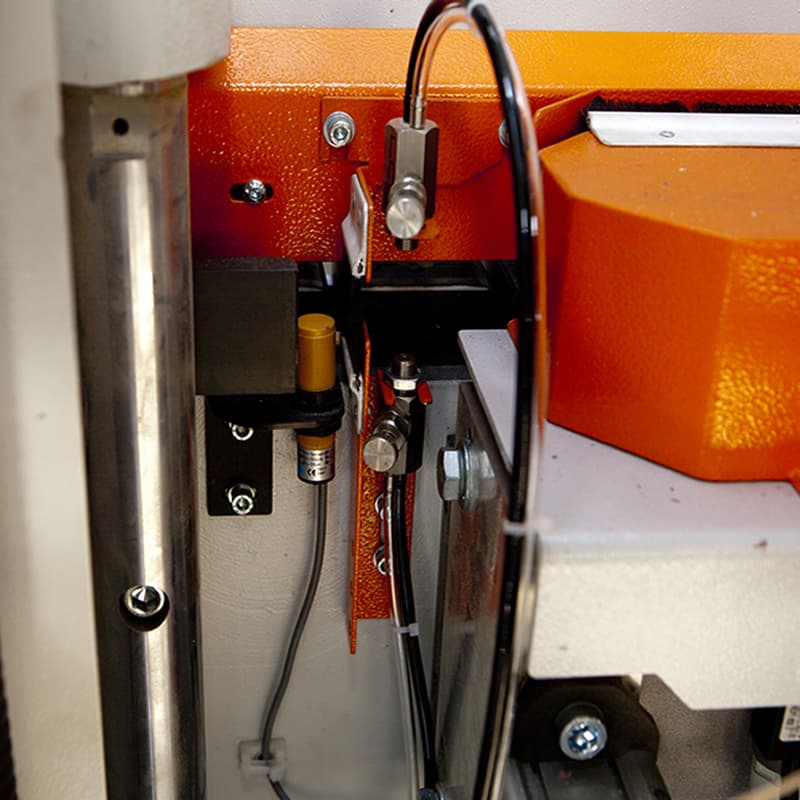

- Front Spray Station;

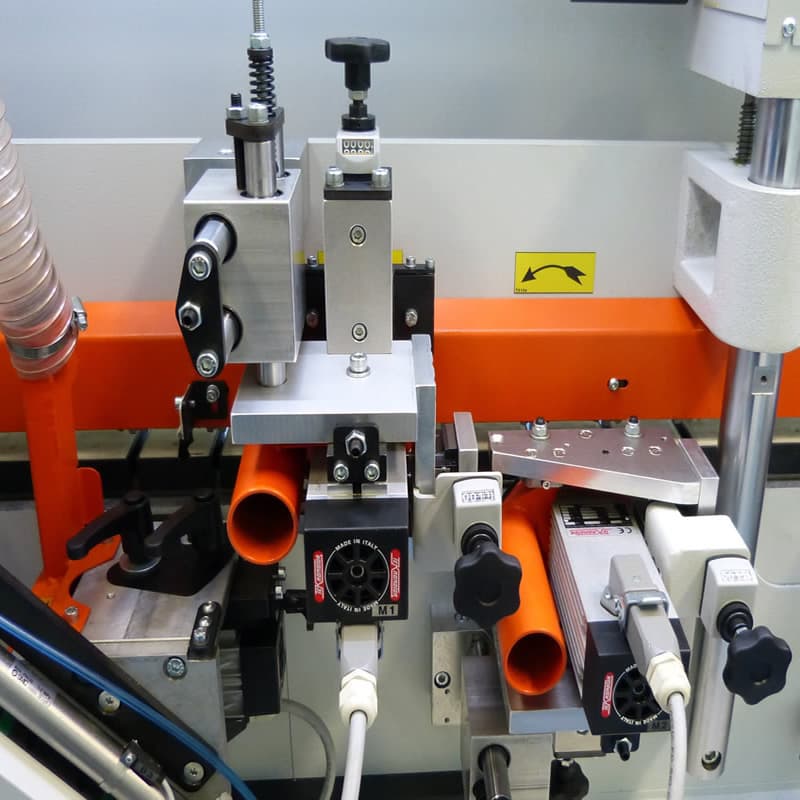

- Pre-milling Station with diamond blades;

- Infrared Light to pre heat the panel in a winter;

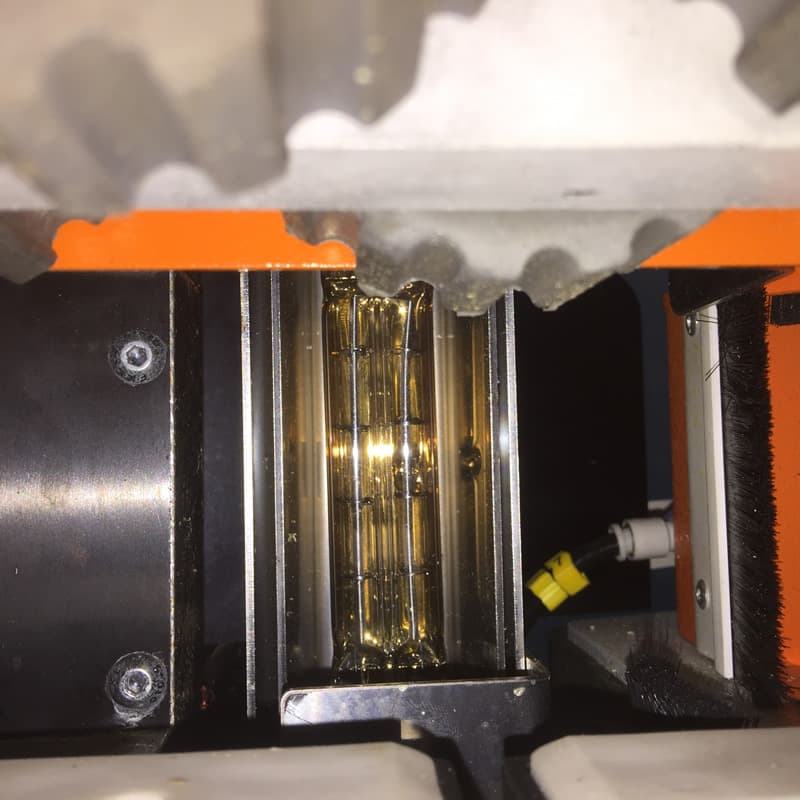

- Easy to set and Quick change Teflon glue tank;

- Three independent pressure rollers controlled by air pressure;

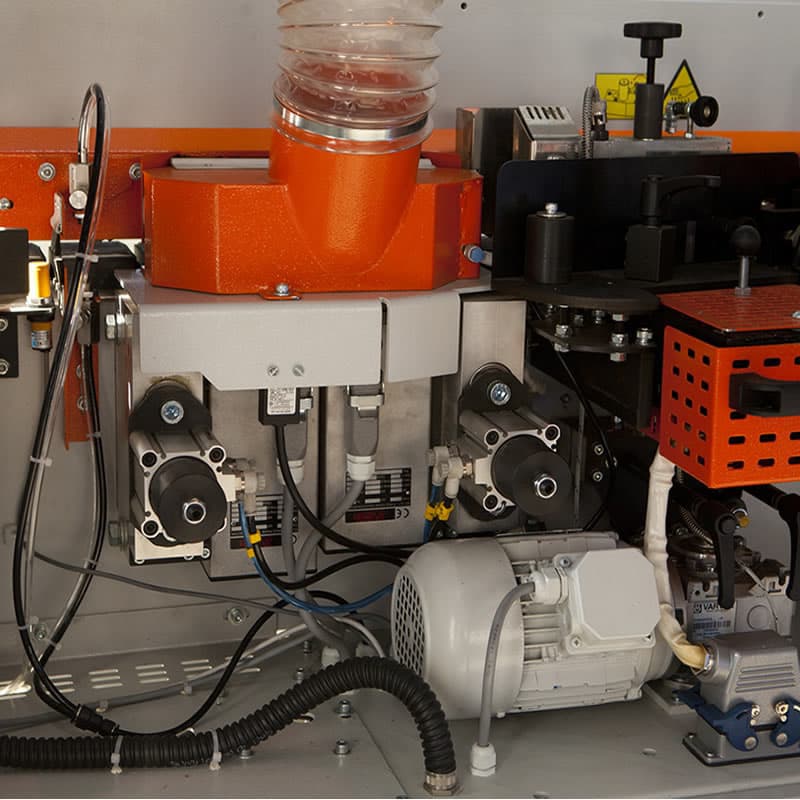

- Two End Saws;

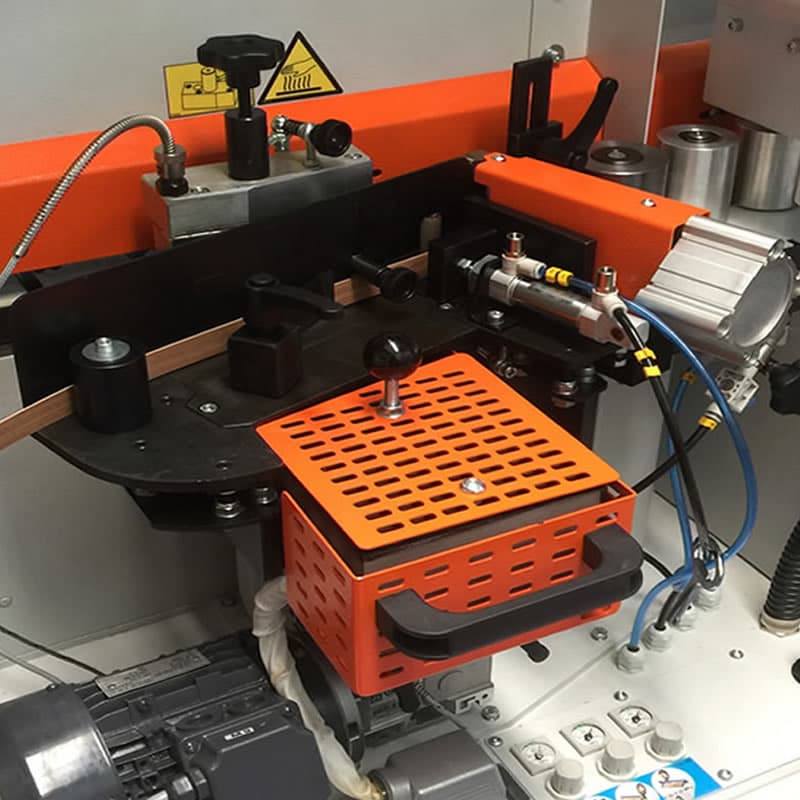

- Top and Bottom Fine Trimming station equiped with a Nesting Kit for doors;

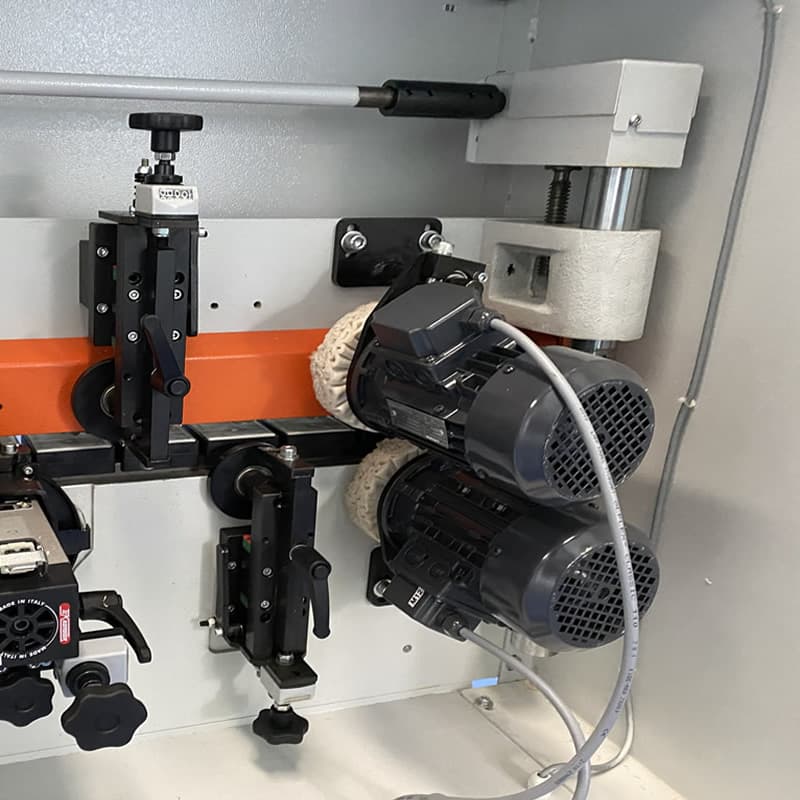

- Twin Corner Rounders for faster trimming;

- Round Scrapers equiped with a Nesting Kit for doors;

- Glue Scrapers equiped with a Nesting Kit for doors;

- Back Spray Station;

- Top and Bottom Buffers;

- Dimensions: 5500 × 1440 × 1730 mm;

- Panel Length: ≥100 mm;

- Panel Thickness: 10~60 mm;

- Feed Speed: 12 - 18 m/min;

- User-friendly Touch Screen;

- Efficient high frequency inverters on motors for saws and trimmers;

- Italian made VarVel gear box with longlife lubrication;

- Italian made HF motors by TeknoMotors;

- Return Conveyor - OPTIONAL;

Price excludes GST, Freight and Installation.