SALE | SERVICE | SPARE PARTS

Edge banding is a vital process in woodworking. It involves applying a strip of material along the edge of a wood panel. This not only enhances the aesthetic appeal but also increases durability.

The importance of edge banding cannot be overstated. It provides a clean, professional finish to furniture and cabinetry. It also protects the edges from damage, ensuring longevity. Edge banding plays a significant role in the woodworking industry. It's used extensively in the manufacture of furniture, cabinets, and other wood-based products. In essence, edge banding is a key process that contributes to the quality and value of finished woodworking products.

TYPES OF EDGE BANDING MACHINES

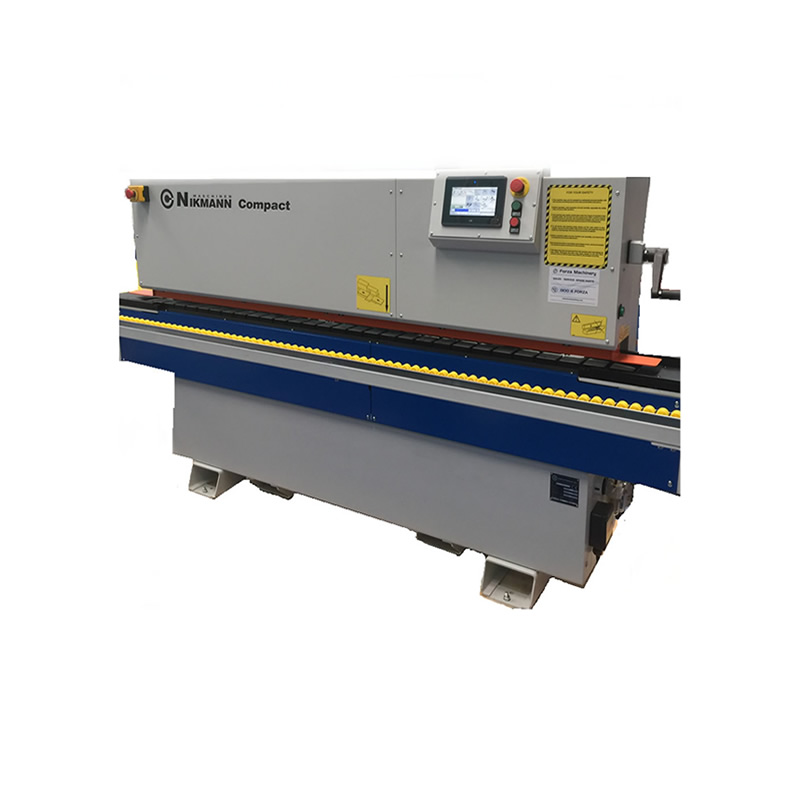

In Australia, you'll find a variety of edgebanders for sale. They range from manual to semi-automatic and automatic edgebanding machines. Each type has its unique features and benefits.

Manual edgebanding machines are ideal for small-scale projects. They are cost-effective and easy to operate. However, they require more manual effort and are less efficient for large production volumes.

Semi-automatic edgebanders offer a balance between cost and efficiency. They automate some processes, reducing manual labor. Yet, they still require operator involvement in certain stages of the edge banding process.

Automatic edgebanding machines are the most advanced. They automate the entire process, from feeding the panel to trimming and finishing the edges. These machines are ideal for large-scale production and deliver high-quality results.

Choosing the right type of edge banding machine depends on your specific needs, production volume, and budget.

We carry edgebanders for sale in multiple sizes and technical specifications.

We also can offer Edgebander Service, Repair and Maintenance for our customers in metro Melbourne, country Victoria and interstate.